Welding Conductor Cross-Sections from 10 to 95 mm² to Terminals

The growing demand for terminal welding systems is driving innovation, especially in areas like electromobility and energy technologies. Ultrasonic welding is often the best choice because it creates strong connections without affecting the conductivity, all while being quick. However, applications are becoming more diverse, requiring compact, adaptable solutions that minimize floor space and can be easily modified for future needs.

Terminal Welding Applications

Terminal welding involves joining cables to contact elements, used for both high-voltage and low-voltage applications. High-voltage applications, such as in the automotive industry, demand very reliable connections that can withstand harsh conditions like vibration and temperature changes for years. Ultrasonic welding effectively meets these needs due to its speed, gentle treatment of materials, low energy consumption, and ability to continuously monitor and document the welding process for high quality.

New Compact Terminal Welding System from Telsonic

Telsonic has expanded its offerings for smaller conductor cross-sections (10 to 95 mm²) with the introduction of the compact TelsoTerminal TT6. Starting in spring 2025, this system will be available in 7.2 kW and 9.6 kW performance classes.

Flexibility in Minimal Space

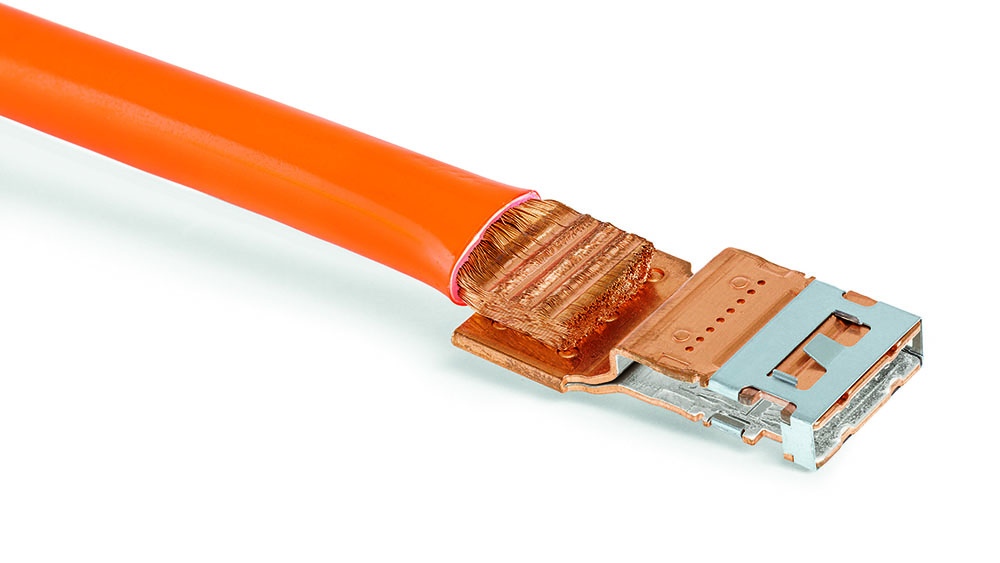

This ultrasonic metal welding system is designed for joining cables to terminals or short terminal-to-terminal connections. It uses the same welding process and components as the larger TelsoTerminal TT7, making it easy to move between machines. However, the new TT6 features a front-loading design for cables and terminals, which saves valuable production space.

The machine is controlled by an easy-to-use 15-inch touchscreen. The generators are optimized for lower power applications. Standard welding capacity ranges from 10 to 70 mm² for the 7.2 kW version and from 16 to 95 mm² for the 9.6 kW version. Welding a 95 mm² copper cable to a terminal takes only 15 seconds, including cooling time.

The ultrasonic generators can be quickly adapted to various applications with different cross-sections, requiring minimal retooling – less than five minutes. Unlike many solutions, no generator upgrades or expensive extra components are needed, ensuring long-term investment security. Users also benefit from low energy use, high process reliability, easy integration with OPC UA, and a long tool lifespan.

Torsional Welding for Strong Connections

Telsonic’s patented PowerWheel® welding technology ensures high contact quality. Welding happens through a rocking, rolling motion directly over the joining area, focusing maximum power in the weld zone. This results in welds that are up to 30% narrower compared to linear systems, saving material and space.

Another advantage is the creation of narrow but thick weld nodes with high strength, reducing the risk of cable breakage. Telsonic’s standard PowerWheel sonotrodes are optimized for both copper and aluminum and meet OEM and wire harness manufacturer specifications, including USCAR 38 (a performance standard for ultrasonic welded wire terminations). The system works with all non-ferrous metals.

Real-Time Measurement and Digital Process Control for Quality

The torsional motion isn’t the only factor in weld quality. The direct vertical force applied to the weld area is also crucial. While many systems only measure pneumatic pressure, weld time, and energy, Telsonic’s system uses an integrated load cell to measure the actual force applied. This allows for precise detection of any deviations during production.

The applied force is measured in Newtons, not pneumatic pressure, making the system independent of the pneumatic environment and easier to adapt to other machines. Weld amplitude is displayed as an absolute value in micrometers (µm), not as a percentage.

Optionally, the system can monitor the converter temperature to prevent overheating. Additional sensors can measure the diameter of inserted cables and the height of terminals to ensure correct parts are used and positioned, reducing material waste. All data is logged and linked to the specific welding process.

Digitalization for Optimal Results

Process and quality data should be integrated with higher-level plant control systems. The TT6 features an OPC UA interface for easy communication with existing production control systems or MES platforms. An optional Java-based MES Connector SDK allows for quick and independent integration into an MES environment. This enables flexible, vendor-independent access to all relevant process and product data for both process optimization and quality assurance.

Digitalization also benefits changeovers between production orders. Digital checklists help prevent errors during tool changes. The system guides operators through the retooling process with a new job loaded. Barcodes on tool documentation can be scanned to verify the correct sonotrode is installed, ensuring all steps are completed correctly before resuming production.

Conclusion

The new terminal welding system offers diverse technological advantages. Its cost-effective and environmentally friendly ultrasonic welding process opens up new application areas where high reliability and minimal space requirements are essential.

Learn more at telsonic.com

About Telsonic

The Swiss Telsonic Group has been providing industrial ultrasonic solutions across Europe, the Americas, and Asia since 1966. With continuous innovation, Telsonic has gained a competitive edge in many applications, offering real value to its customers. This owner-managed company specializes in ultrasonic welding of plastics and metals, as well as ultrasonic cleaning and sieving. Customers in the automotive, packaging, and medical technology industries worldwide appreciate Telsonic’s wide range of ultrasonic components and complete welding systems for machine builders and end-users.

I’m Rohan Mehta, the voice behind KhelRe—a trusted and steadily growing blog dedicated to electric vehicles (EVs) in India. With over five years of experience as a tech and automotive blogger, I turned my frustrations with owning an EV into a mission: to help others make more intelligent choices in this fast-evolving world of electric mobility.

I’ve been an early adopter of EV technology—I repurchased my first electric scooter in 2019. That experience opened my eyes to both the promises and the pitfalls of this new mode of transport. From slow charging times and range anxiety to misleading specs and hidden costs, I’ve faced it all. But instead of walking away, I decided to write about it.

That’s how KhelRe was born—a no-nonsense, hands-on blog where I share practical, real-world reviews of EV cars, bikes, and scooters. I break down features, range, performance, and pricing from a user-first perspective. I take pride in simplifying complex tech into clear, valuable insights—offering tips, ownership stories, and advice you won’t find in flashy press releases or sales brochures.

Whether you’re a first-time EV buyer or just a curious auto enthusiast, my goal is to help you navigate the EV landscape with confidence. My motto: “EV knowledge should come from experience, not just brochures.”

When I’m not test-driving the latest e-scooter or comparing charging networks, you’ll probably find me tinkering with my garage EV setup, chatting with fellow enthusiasts online, or sipping chai while writing my next blog post from a cosy local café.